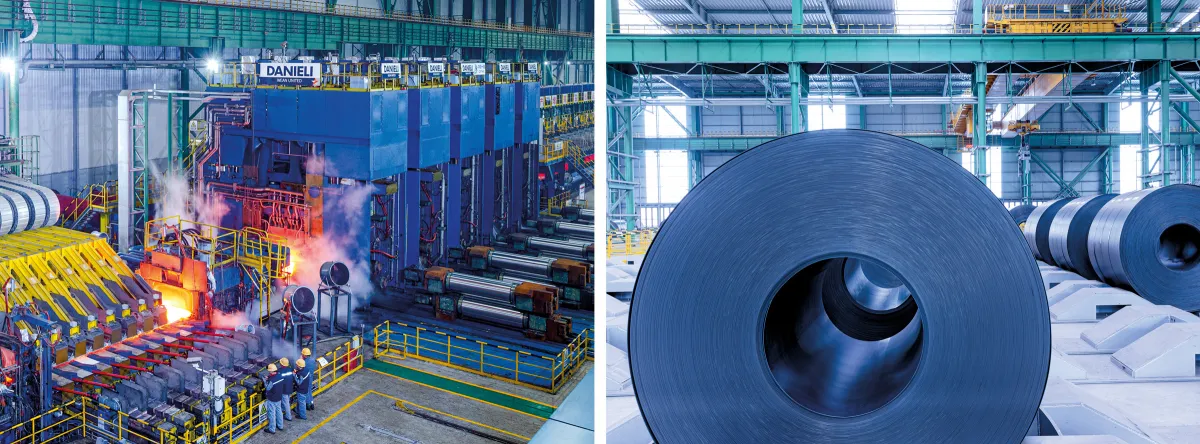

QSP-DUE

for hot-rolled coils

Danieli Universal Endless is the Danieli original and effective way to produce flat or long products in three rolling modes in the same line –endless, semi-endless, coil-to coil.

The core of the QSP-DUE lines for Quality Strip Production are the Danieli-patented DySenCaster and the mill layout.

The vertical-curve, Dynamic Submerged Entry Nozzle Caster adopts flat moulds which today allow the production of peritectic, automotive-exposed and other extra-advanced steel grades.

Performing at high-output rates, high speeds and thicknesses of 140 to 160 mm, Danieli DySenCaster ensures a continuous endless casting-rolling process.

Danieli QSP-DUE lines feature a split design concept with a dynamic induction heater between roughing and finishing mills to control (heat up, equalize, edge heat) the transfer bar temperature on-demand.

This design allows endless operation, ensuring rolling stability, with tight geometrical and mechanical tolerances, and reducing cobble risks, all of which are essential for producing ultra-thin gauges as low as 0.7 to 0.9 mm.

You can do so by followingand dragging the slider to the right

QSP-DUE accommodates flexible production in endless, semi-endless and coil-to-coil modes, of ultra-thin to ultra-thick gauges, addressing all industry needs, including automotive and API grades for Arctic applications.

The first QSP-DUE is in operation since 2019 at Shougang Jingtang, in China: it is a major technology milestone and current benchmark. Producing over 2.1 million tons yearly in endless, semi-endless and coil-to-coil modes, this QSP-DUE plant specializes mainly in ultra-thin and thin gauges from 0.8 to 2 mm, and achieving full production ramp-up in less than 12 months.

The Yukun plant, started in 2024, in China, will be the world's most productive thin-slab casting and rolling facility. With two slab casters, one of which is directly connected to the hot-strip mill, it will produce 4.5+ million tons per year of hot-rolled coils in three possible rolling modes. The caster performed 145-mm-thick slabs, the thickest slab ever produced by a caster operating with a funnel mould.

QSP-DUE #1

Shougang Jingtang, China

in operation since 2019

2.1 Mtpy

QSP-DUE #2

Yukun, China

in operation since 2024

4.5+ Mtpy