Q-Heat

induction heaters

Induction heating is the most environmentally friendly solution for reaching the required rolling temperature without using gas, lowering emissions and drastically reducing scale formation.

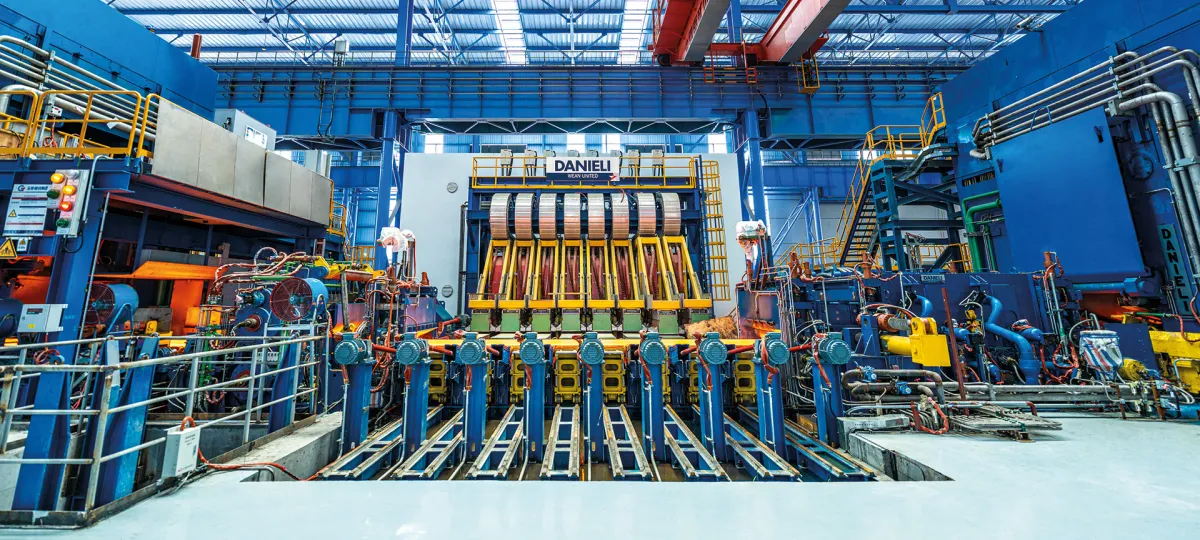

Modular and maintenance-friendly, Danieli Automation Q-Heat® induction heaters allow quality, efficient, flexible, accurate and quick temperature control for casting-rolling processes, in new or existing flat- and long-product plants, lowering emissions and drastically reducing scale formation.

Each individual induction coil is independently controlled and can be individually turned off, making it possible to save energy and achieve better tail-to-head material temperature equalization, discharging the proper amount of energy on each part of the material. Danieli Q-Heat heaters are ready in real time: no need for long start and stop sequences, as with conventional reheating furnaces.

Powered by HiPAC high-performance controller featuring native integration with Danieli L1 and L2 automation, Q-Heat systems provide feedforward / feedback bar-temperature control. Additionally, Danieli Q-Heat can be powered by renewable energy sources through the original Danieli Q-Jenius system.

In flat-product rolling, Q-Heat modules are installed between roughing and finishing mills of QSP plants running in endless and semi-endless mode, to guarantee perfect temperature of the transfer bar.

In direct casting-rolling plants, billets and blooms are directly transferred via induction heaters from the continuous casting machine to the rolling mill, without any intermediate gas-based reheating furnace.

Furthermore, induction heating can be applied for cold rolling of certain quality steels, gas-free strip heating in processing lines, and in thermal treatment lines for quality steel bars.