Q3 digital process-automation solutions

Danieli process controls and automation systems are evolving towards a new manufacturing organization, strongly supported by modern digital assets, where processes are automatically and autonomously improved.

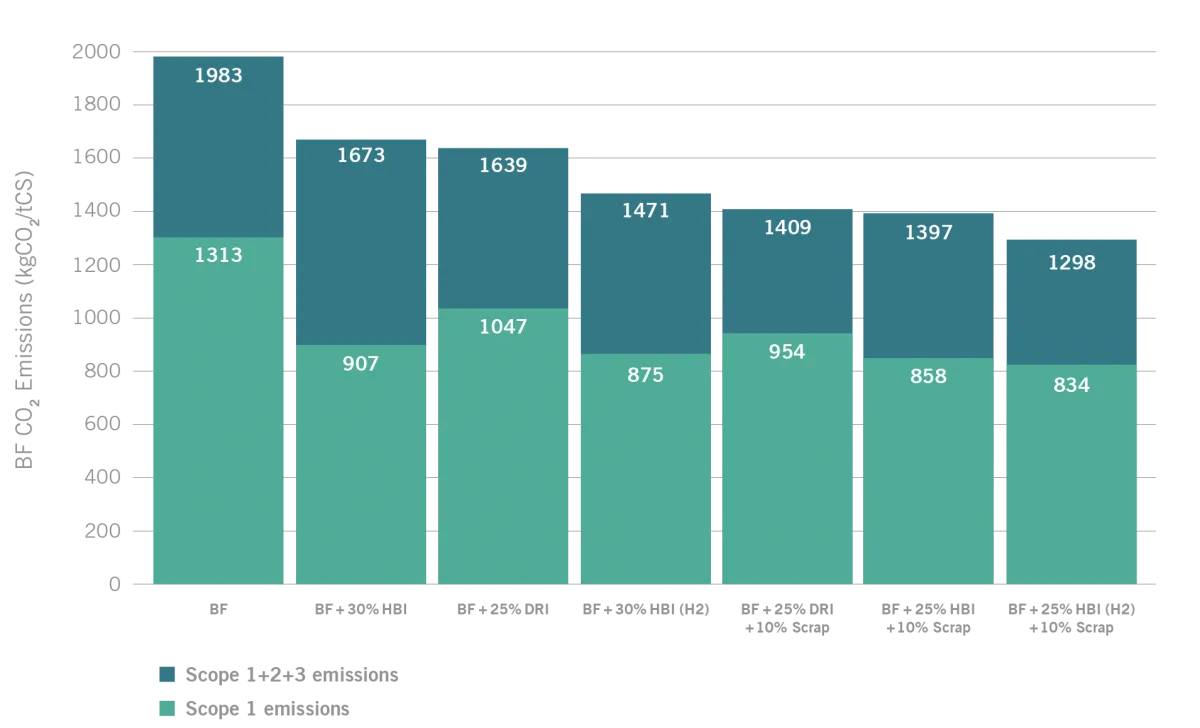

To advance decarbonization in steelmaking, techniques that optimize blast-furnace burdens using pellets and metallics are essential. In fact, this strategy can reduce CO2 emissions significantly and is immediately deployable, contrasting with hydrogen-based methods that depend on green power and water availability. Furthermore, hydrogen is not easily stored and transported.

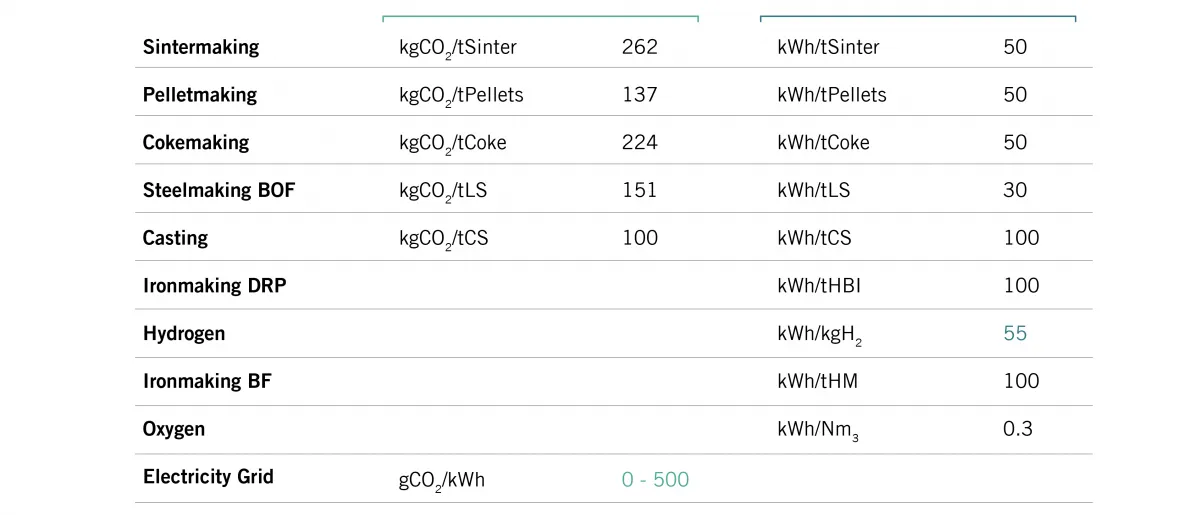

The sum of scope 1 + scope 2 emissions has to be considered, and the Danieli Corus solution proves its sustainability:

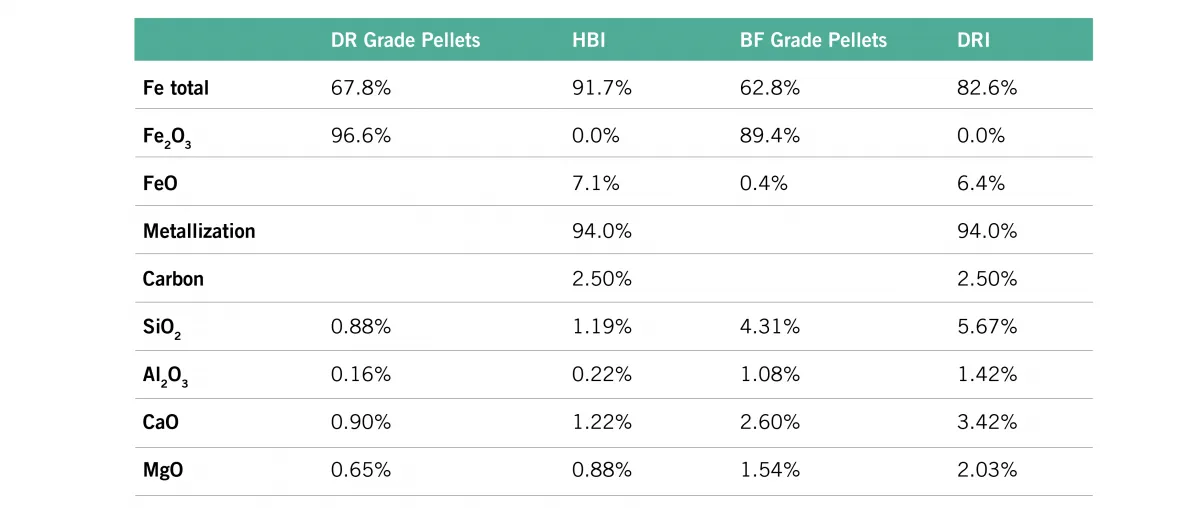

Process parameters for scrap (Fe 95% db), HBI (Fe 91% db) and DRI (Fe 82% db) have been carefully assessed. Process stability must be ensured by controlling softening and melting in the cohesive zone. The right burden distribution, sizing, and metallics composition are crucial for stable melting and operations.

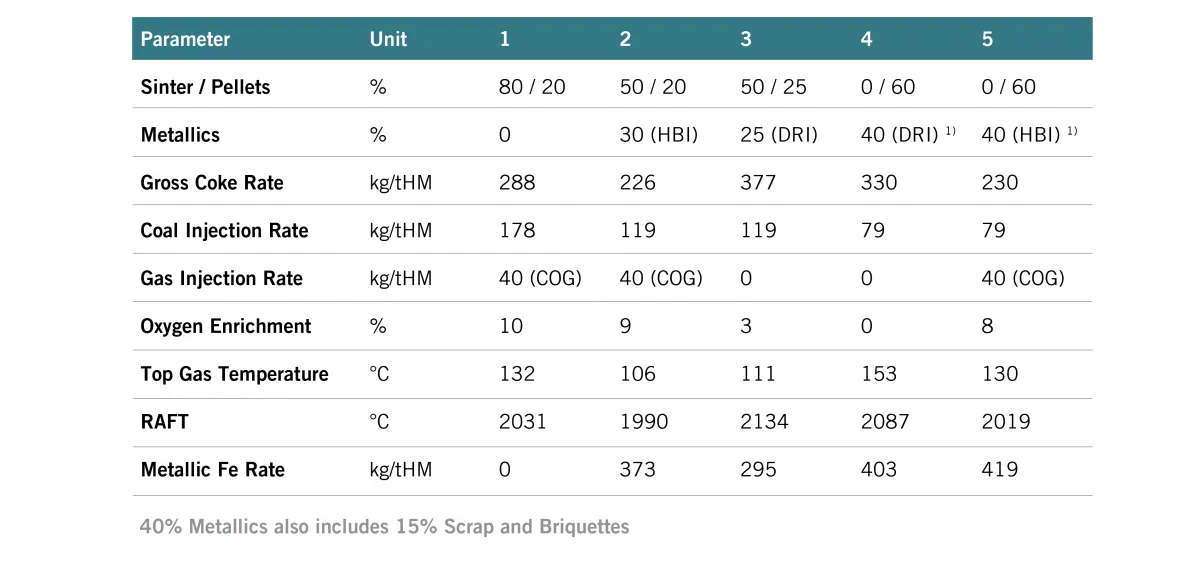

Charging 40% metallics (DRI/HBI ???) keeping similar gas utilization in the BF??? is possible, by optimizing burden distribution and metallics composition while maintaining a proper burden flow profile that ensures BF stable operation.

Danieli Corus steady-state, three-stage heat and mass balance calculations can determine the proper and optimized coke rate, raceway, and top-gas temperatures for various burden compositions.

Sintermaking emits more CO2 than pelletmaking, thus the use of pellets reduces emissions.

DRI, with lower iron content, is assumed to be produced at the integrated steelmaking plant.

Also, the increment of the metallics (scrap) in BOF steelmaking further reduce carbon emissions.

The sum of the applied techniques potentially reduces blast-furnace direct carbon emissions below 1000 kgCO2/tHM.