Electric

heating systems

Electrification in steelmaking can be conveniently applied to long- and flat-product rolling, and in strip-processing lines for galvanized and coated strip.

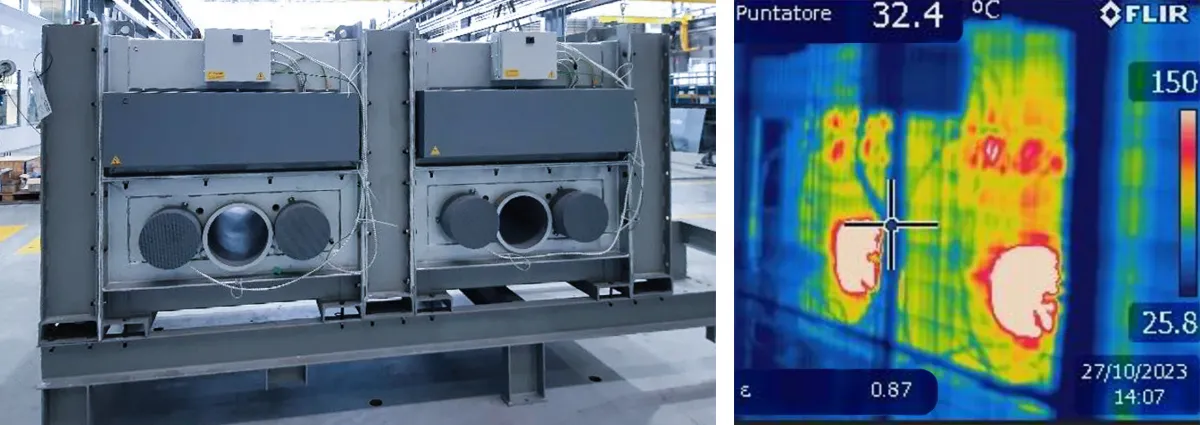

Among the results of the intensive R&D activities pursued by specialized Danieli Centro Combustion and Danieli Olivotto Ferré divisions at the dedicated research centre in Savona is the design of new, innovative electric heating systems for reheating furnaces for long and flat products, and heat-treatment furnaces for strip-processing lines.

Danieli fully electric tunnel furnaces combine induction and electrical-resistance heating for emission reduction; induction modules are foreseen upstream and downstream a tunnel furnace section fully equipped with electrical resistance. The provision of dry rolls in the tunnel furnace also delivers important electrical energy consumption savings, and excellent strip quality.

A first electric tunnel furnace was ordered by SSAB, part of the fossil-free steel minimill project for hot-rolled coils in Luleå, Sweden, which is being supplied by Danieli.

On the long-products operation side, a fossil-free, high-temperature tunnel soaking furnace has been implemented and is operating at Fagersta in Sweden, where stainless steel billets are held at 1250°C, ready to serve the rolling mill.

The replacement of fossil fuels as primary source of gas thermal power plays a key role in transition to Green Steel production.