CUSTOMER SERVICE

Mandrels for flat applications

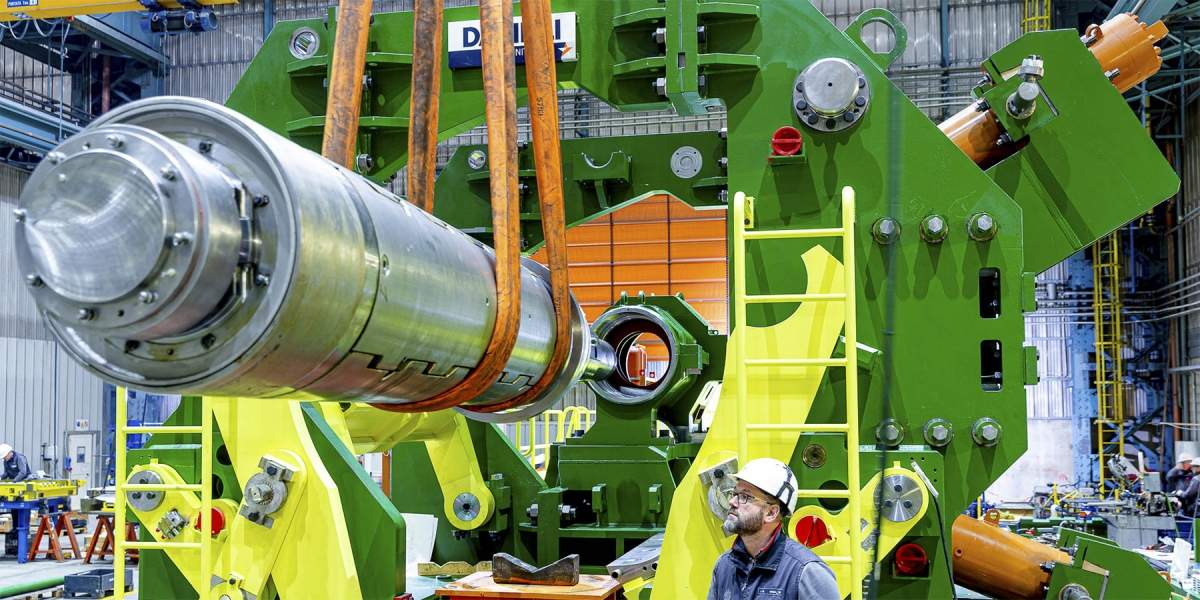

Latest generation of rolling mill equipment thanks to Danieli's expertise in design and manufacturing for metals production.

The perfect mixture of being the highest quality manufacturer combined with the reliability of a workshop that works with you on a daily basis.

We fulfill a complete range of needs thanks to proprietary world-wide workshops, flexibility and affordable solutions.

Danieli Service’s Mandrels’ section focuses on our customers’ results.

Hot Strip Mill Down-Coilers

COILING

- Narrow strips (in widths up to 800mm)

- High-strength materials HSS (with limited max. thicknesses by max. hot yield point) and widths of 800-2100mm

- Ultra-thin material in endless strip production (QSP-Plant), up to 0.6mm

- Painting, assembly of any additional parts and delivery

POWERFUL DOWN-COILER

- Coiling of thick strip up to 25.4mm

- Coiling at low strip temperature up to 500°C

- Best quality strip shape

- Straight edges and tight windings

- Best head/tail quality

- Full process stability, both for thin/thick gauge

- Coiling of special HSS up to X100

- Significantly reduced operating/maintenance costs

- ROI: 2-3 years

- eliable strip quality

- Advanced markets such as automotive and API grade pipe steels

The advantages of the Powerful Down-Coiler can be seen in a prime quality increase of 0.1%, yield increase due to fewer cobbles, product mix increase of more than 25%, –2.0% reduction in coils which, due to telescopicity, require recoiling.

Cold Application Mandrels

HIGHLIGHTS

- Low/Medium/High tension applications

- Fast supply chain

- Improved oil-less operation

- Maximum quality strip finishing

- Latest materials/treatments and innovations available

- Highly demanding automotive lines

ALUMINIUM SECTOR

- Full knowledge of process

- Danieli Fröhling / Danieli Fata Hunter

REFURBISHMENT

- Technicians availability to check mandrel conditions on-site

- Fully equipped workshop

- Fully Standardized refurbishment procedure

- Highly skilled workers

SPARE COMPONENTS

- Segments

- Shafts

- Pull rods

- Sleeves

- Gear drives

- Hydraulic cylinders

BACKGROUND

- Fully dedicated technology-design department

- Tailored to meet customers’ demands

- Hydraulic testing cell available in each Danieli shop

Scorecard

DANIELI SUPPLY TIMELINE 1990-2020

- #225 Payoff Reels

- #204 Tension Reels

- #71 Down-coilers

- Over 2000 Segments

WORLDWIDE OVERVIEW

- Over 9000 Employees (‘19)

- Over 2000m2 of Workshops

- Over 400t Cranes capabilities

TECHNICAL ASSISTANCE

Technical assistance target consists of sequential and measurable steps, necessary to achieve goals in a scheduled period of time, with the focus on final customer’s satisfaction.

Danieli believes in collaboration as first act to reach the best results. During the past decades Danieli has set up a dedicated structure and professional teams, located worldwide, able to take prompt action, thanks to the support offered by skilled designers and technological departments in Danieli HQ.

Danieli Service team has faced many complicated situations due to the average age of mill (˜40 years) and the non-standard behaviors of mandrels, establishing specific rules and steps to complete the task, and developing ‘Danieli’s manual of intervention’.

This approach is applied to Danieli Plants, as well as to non-Danieli plants.