Digital scrap

optimization and

management

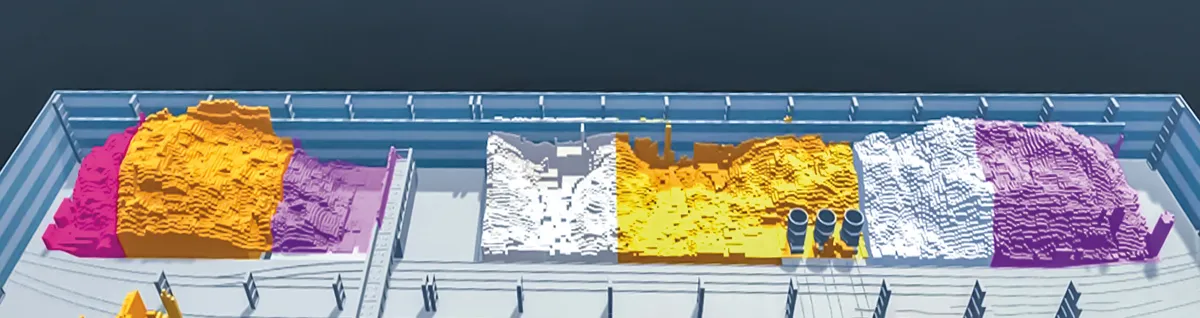

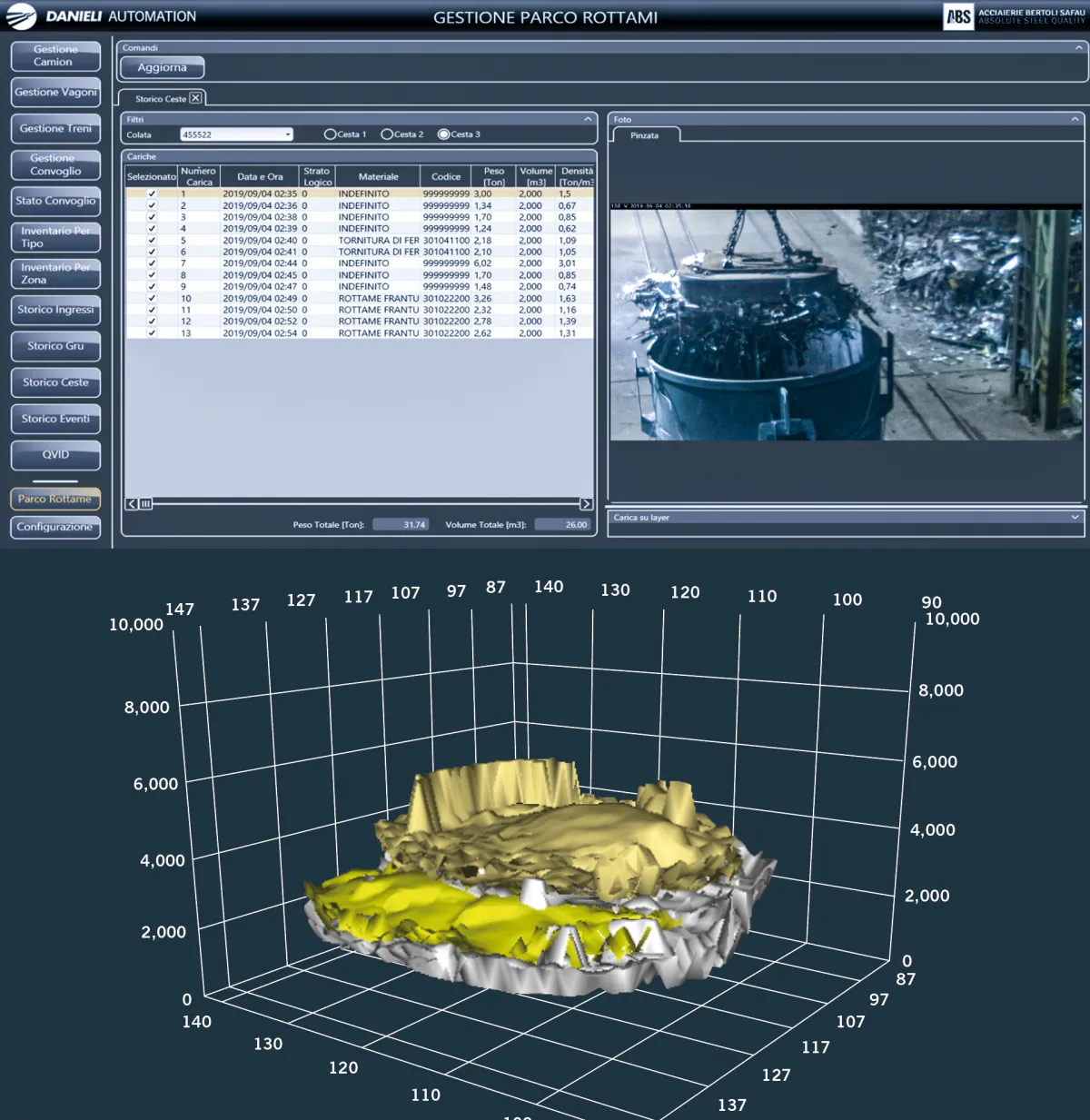

Q-SYM2 is the Danieli Automation advanced, unmanned scrap-optimization and management system.

Together with scrap densification, scrap cleaning and chemical control achieved through the operation of Danieli Centro Recycling in-line shredders, shears and separation lines, results in increased EAF melting efficiency and lower production costs.

Communicating with the Danieli Q-Melt advanced process control, Q-SYM2 contributes to a dynamic and automatic optimization of the melting profile.

Rooted in artificial intelligence, Q-SYM2 provides the furnace with the best classified raw material and scrap-processing machine interaction, according to EAF/scrap bay needs.

Scrap is mapped from its arrival to the bay at the steelmaking plant to its use in the furnace, to ensure the incoming material quality and quantity according to the purchase order.

Real-time tracking allows for prompt, effective and simplified claim procedures when needed, thanks to artificial intelligence that makes possible automatic image acquisition and analysis.

Continuous, real-time scrap inventory is available, reducing human errors and operational times. Scrap tracking handles scrap movement within the yard including loading and unloading bays.

Furthemore, native integration within the overhead cranes improves the yard management yield.

Accurate “crane mission-generation” results in optimized crane utilization, with repetitive actions promptly executed based on scheduled and predetermined patterns.

More and more steelmakers are installing automatic scrap yards and scrap preparation lines at their production sites. To mention the most recent ones, an automatic scrap yard will feed the new EAFs at Algoma Steel, whilst five scrap-recycling plants were ordered by the Mexican steelmaker Deacero.

You can do so by followingand dragging the slider to the right