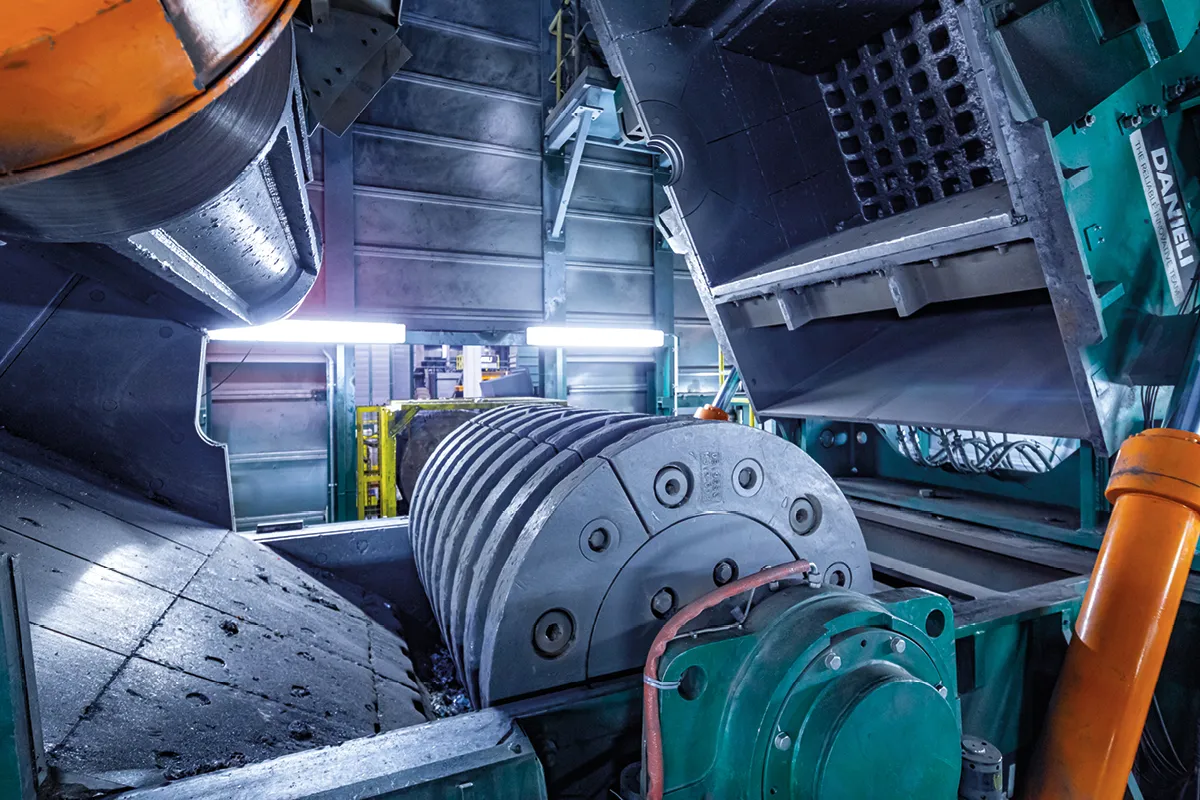

Scrap processing and optimization: the Danieli scrap-to-melt system

Exploiting the benefits of effective, in-house scrap processing to improve EAF efficiency, while reducing carbon emissions

You can do so by followingand dragging the slider to the right

Danieli Scrap to Melt -DSTM is the Danieli answer to reduce operating costs and CO2 emissions by processing and controlling the scrap before charging it into the EAF, either by bucket or continuous charge enhancing melting efficiency.

The innovative and patented DSTM technology, developed by Danieli Centro Recycling, is the result of combining and integrating three processes of scrap treatment: densification, cleaning and chemical control. The combination of these processes makes it possible to separate the processed scrap into batches, based on the meltshop chemical composition requirements.

In the first step, densification, incoming scrap is processed using shears and/or shredders to achieve the proper charge density prior to melting.

Next, the sheared/shredded material is cleaned, and inert and nonferrous elements are removed by a combination of air separation and magnet systems, improving melting efficiency and reducing CO2 emissions.

In the final step, to control the furnace charge chemistry, the Danieli analyzer detects the chemical concentration of the alloys like Cu, Ni, Cr, or Mn, and integrates the feedback to categorize the scrap by its chemical concentration.

The production cycle is automatic and continuous, and no operator control is required after the charging of the scrap (into the shear or the shredder), ensuring high-level performances and reliability.

You can do so by followingand dragging the slider to the right

Case study at European steelplant

Concerning the mass of inert contaminants of scrap (a combination of oxides comprised mainly of rust, soil, cement, etc., typically containing 40% of SiO2), a reduction of just 1% over the total mass of scrap charged results in:

Increased productivity

by over 2%

Saving of ≈10 kWh/tls

of electrical energy

Reduced usage of slag-builders

by ≈6 kg/tls

(maintaining the same slag basicity)

Additional benefits can be assessed on electrodes, methane and carbon consumption, resulting in total direct CO2 emission reduction from the EAF by over 1%.

Removal of 100 kg of organic material in a 100-ton furnace will reduce the total direct CO2 emission of the EAF by almost 3% (Scope 1 CO2).

Within DSTM, Danieli Q-SYM2 supports scrap processing, tracing the input and output scrap at each process step, organizing machine activities based on the scrap requested by the melting process.