News & events

In this section you will find all the latest news of the Danieli Group. Selecting the categories below, you can see News, Records, Start-ups, New Orders.

new orders

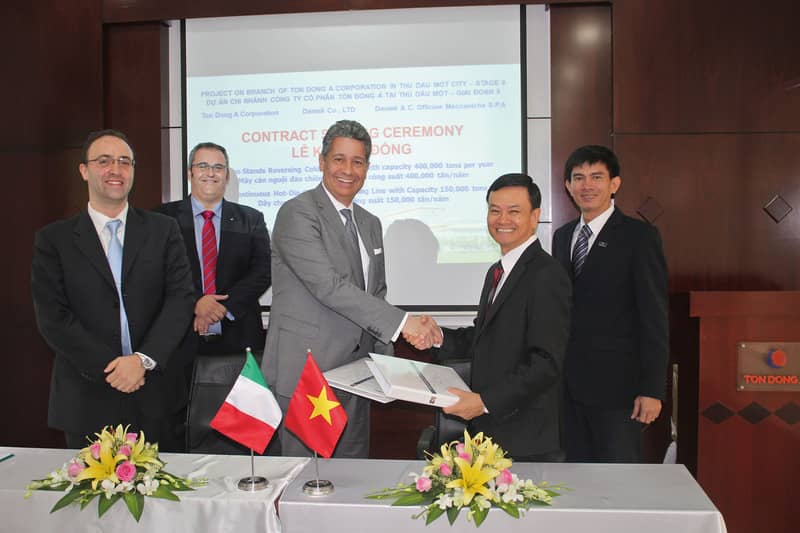

2016, 16th February

New Danieli Cold Rolling Mill and HDGL at Ton Dong A, Vietnam

Danieli will supply a new HDGL and a two-stand 4-Hi CRM for the production of GL coated strip and thin low-carbon strip, for the new facility in Binh Dong, Vietnam

After the first order awarded in 2012, Ton Dong A confirmed its satisfaction with the “product” supplied by Danieli, placing another order for its Cold Mill Complex in Binh Duong, a province of Vietnam.

The new Hot Dip Galvanizing Line is designed for a total capacity of 150,000 tpy of finished coils for thin strip with thicknesses from 0.16 to 1.0 mm, and widths up to 1,250 mm. This line guarantees some of the best parameters on the market for GL zinc coating, producing thin GL coatings down to 40 g/m2 on each side at 150 m/min. The annealing furnace in the process section, supplied by Danieli Centro Combustion, will be equipped with a recuperative room, free flame section, “U-Type” radiant tube section, and the jet cooling section for CD, DQ and FH grades. The final zinc thickness will be closely controlled by the X-Jet Danieli Kohler air wiping system. After passing through the zinc pot to improve elongation, roughness and flatness, the strip will enter Danieli’s Q-Surface system (skin-pass and tension leveler). Danieli Automation will develop and supply the electrical and automation part of the line.

The new two-stand 4-Hi Cold Reversing Mill is designed to achieve a total annual production of 400,000 tpy of low-carbon cold-rolled strip, with a minimum thickness of 0.11 mm and a maximum width of 1,250 mm. The mill runs on odd and even passes, since it is equipped with selective roll coolant systems and shapemeter rolls. Three thickness gauges and laser meters are provided for mass flow control. The automatic control of cold rolling and the advanced level 2 for the automation system are developed and supplied by Danieli Automation.

Thanks to the combined use of mechanics and rolling models in the software, Danieli is able to offer high performance parameters in terms of thickness tolerance and flatness.

With this project, Danieli proves once again that it is a world-wide leader in advanced cold rolling equipment and processing lines.