News & events

In this section you will find all the latest news of the Danieli Group. Selecting the categories below, you can see News, Records, Start-ups, New Orders.

top performances

2016, 17th February

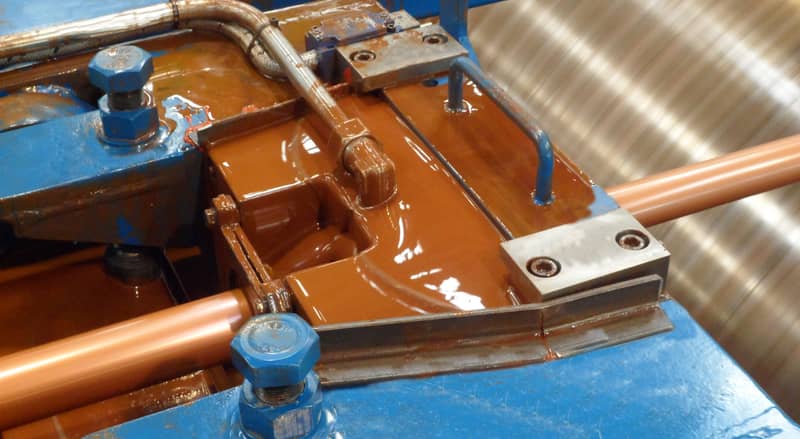

Eccentricity reduced by 5-6% in 6 months: superb performance with the latest improvements to the copper tube plant at Foma - Italy

Only six months after the revamp Foma improved its copper tube quality by reducing the eccentricity of drawn tubes by 5-6%, and increasing material yield

Beginning of 2014: Foma and Danieli agreed to develop a series of systems to reduce the tube eccentricity generated by the existing technological equipment installed in the production plant.

First of all, a new drawing die block was installed on the existing Bull Block drawing machine in order to keep the eccentricity below 10%. Then a couple of months later Danieli Centro Maskin manufactured two systems and installed them on the existing Danieli chain track drawing machine for real-time tube eccentricity measurements, adjustments, controls and material classification. These systems are called DEC+DED systems (Danieli Eccentricity Control + Danieli Eccentricity Detection). This plant works in cascade configuration, starting from an extruded tube which then passes through the Danieli chain track drawing machine fitted with the DEC+DED systems.

These two new technological packages installed on the existing machines are providing the customer with significant advantages in terms of material quality, control and certification, with eccentricity values of 5-6%.