News & events

In this section you will find all the latest news of the Danieli Group. Selecting the categories below, you can see News, Records, Start-ups, New Orders.

list_newstype_**

2015, 27th October

New Rotoforge plant started-up at ABS (Italy)

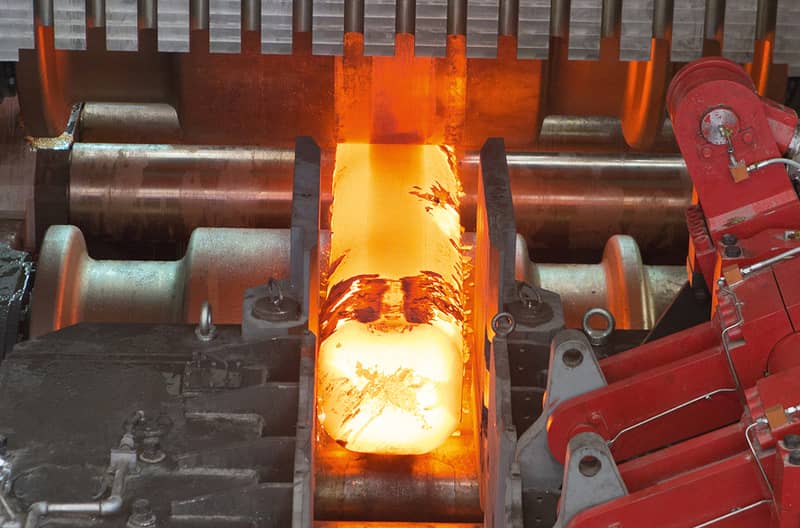

A breakthrough innovation in Heavy SBQ production leading to superior product characteristics

Danieli Rotoforge process is an ideal alternative solution to the production of high quality material via forging, with the efficiency and profitability of a rolling mill.

This plant, inaugurated in October by Italy’s Prime Minister, Mr. Matteo Renzi, produces the same internal quality in cast materials that is achievable by forging, thanks to the features of the new design “Rf” heavy-duty stand: it imparts the same tensile strengh to the core of the bloom that is found in materials produced by a forging process.

Rotoforge offers remarkable advantages, such as:

- High internal quality, comparable to that of a forged product

- Improved size quality and tolerances

- High reduction ratio (>1:3) for rounds up to 500 mm and equivalent squares

- High productivity

- Short lead times and fast response to the market demand

As a result of the high drafting per pass, “Rotoforged” material has thin grain size and exceptional soundness (FBH<2mm), while the rolling process ensures excellent surface characteristics, high productivity and hence dramatic reduction of transformation costs (no additional turning is required).

In addition, ABS gains benefits in productivity by supplying Rotoforge with high-uality, 850 mm dia. blooms produced by the nearby Continuous Casting Machine #3.

The largest of its kind, and a benchmark for bloom casting, CCM #3 is highly competitive in quality, and offers an enhanced product range including ternary grades, while ensuring high productivity and metallic yield.

The Rotoforge is truly a breakthrough innovation that advances ABS one step ahead of competitors.