News & events

In this section you will find all the latest news of the Danieli Group. Selecting the categories below, you can see News, Records, Start-ups, New Orders.

service news

2015, 10th August

Danieli Transmissions successfully revamps Hoesch Hohenlimburg’s HSM drive trains for improved rolling performances

Hoesch Hohenlimburg, a company of ThyssenKrupp Steel Europe, is a leading supplier of hot-rolled steel strip based in Hagen, Westfalen, Germany. The plant is strategically important for the Group because it produces a steel product characterize by significant technical know-how in order to fulfill the needs of individual customers, while providing solutions to problems

Hoesch Hohenlimburg, a company of ThyssenKrupp Steel Europe, is a leading supplier of hot-rolled steel strip based in Hagen, Westfalen, Germany. The plant is strategically important for the Group because it produces a steel product characterize by significant technical know-how in order to fulfill the needs of individual customers, while providing solutions to problems. The high-precision and high-strength hot rolled steel from Hoesch Hohenlimburg are mainly used in cold rolled and automotive industries for special applications. As part of a continuous process to improve quality and productivity, one of their latest major upgrades was on the drive trains of the first two finishing stands G11 and G12, for the purpose of boosting the rolling force through higher torque and increasing the rolling speed.

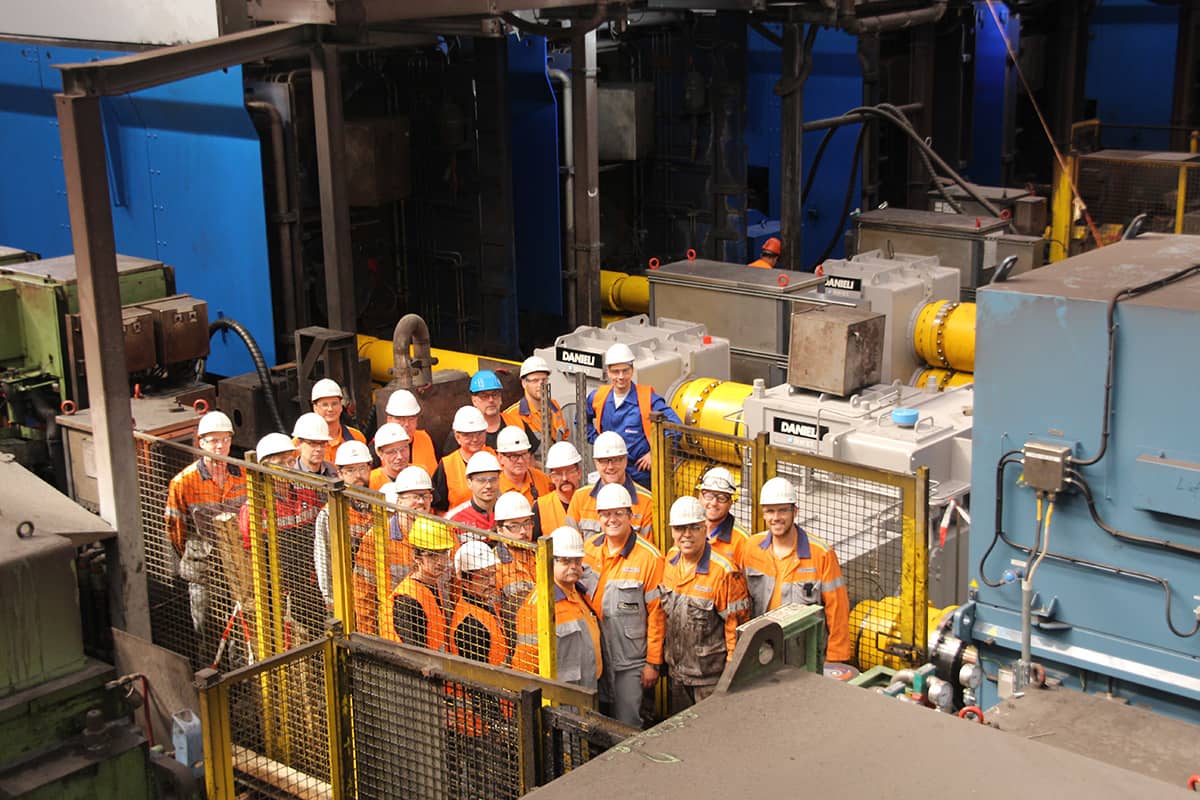

In November 2014, Hoesch Hohenlimburg awarded Danieli Transmissions an order for the design and supply of new gearboxes, safety couplings and latest-generation oil-lubricated spindles to deliver increased torque and power to the rolling stands. One of the main challenges was to avoid making any changes to the civil works and reutilize the anchor bolts of the existing equipment. Danieli was chosen because it offered the best technical solution and was able to guarantee that the work would be done during the planned shut-down of the mill. The project was completed right on time within a nine-month period, to the full satisfaction of the customer.

The project was developed thanks to Danieli’s own in-house design, and included heat treatment, machining, assembly, testing, erection and commissioning under a single point of responsibility. It started with an on-site survey where laser measurements were taken, followed by the design phase with the final approval of the customer, inspection of rough parts at the plants of sub-suppliers, quality certification and regular inspections by the customer at Danieli workshops to evaluate job progress. The machines were then tested at Danieli, with final acceptance, erection and commissioning performed during the scheduled shut-down.

Production started regularly on Sunday night respecting the required performances.

Dr. Overrath, Chairman of the Board of Hoesch Hohenlimburg, has expressed his congratulations, confirming the success of this project as a good example of perfect team work between the parties.