AUTOMATION

MD2000

Hot & cold magnetic detector family

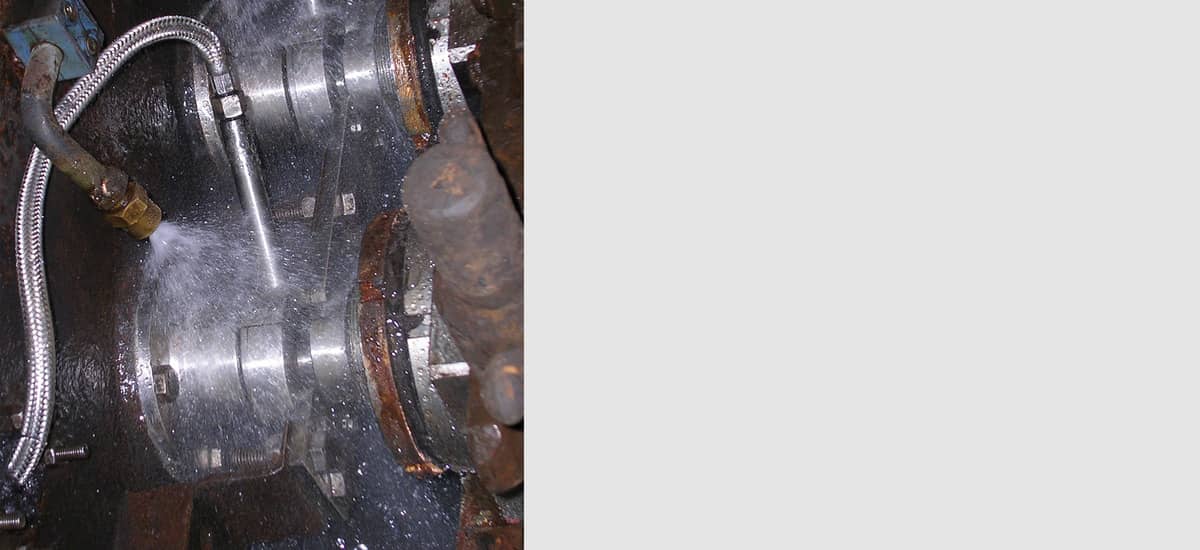

The MD2000 series is the ideal solution for metal detection in harsh environments where infrared detection is not reliable due to vibrations, water or steam presence. This detector family finds metal presence by means of a magnetic field.

The measurement principle is based on eddy currents generated on the surface of a bar by a variable magnetic field. An excitation coil induces eddy currents in the bar. The reaction field produced by the eddy currents is detected and converted into electrical signals by a receiving coil. A digital output is activated by the presence of a bar inside the detection ring-head. An embedded micro-controller checks the system state and dynamically sets sensitivity levels to guarantee optimal performance. A number of different models cover a wide range of applications, to be chosen accordingly to the dimensions of the material to be detected. Moreover, fast running wires can also be reliably detected. The high quality and reliability inherent in DANIELI AUTOMATION detectors gives our customers the benefit of a 3-year warrantee period.

HIGHLIGHTS

- Automatic setup of the detection threshold

- Very thin bar (wire) detection capability (down to 4 mm)

- Built-in test coil for on-line check of device functionality (useful for ghost rolling)

- Full electrical compatibility with optical HMD’s

- Self testing function

- Rugged maintenance free detection probes

- Reliable presence detection in any situation where infrared sensors can easily fail

- Hot or cold metal detection

- Not affected by ambient light or reflections unlike low temperature HMD’s

- Detection independent from material temperature

- Not affected by steam, fumes, dust, oil or water

- Compact dimensions