AUTOMATION

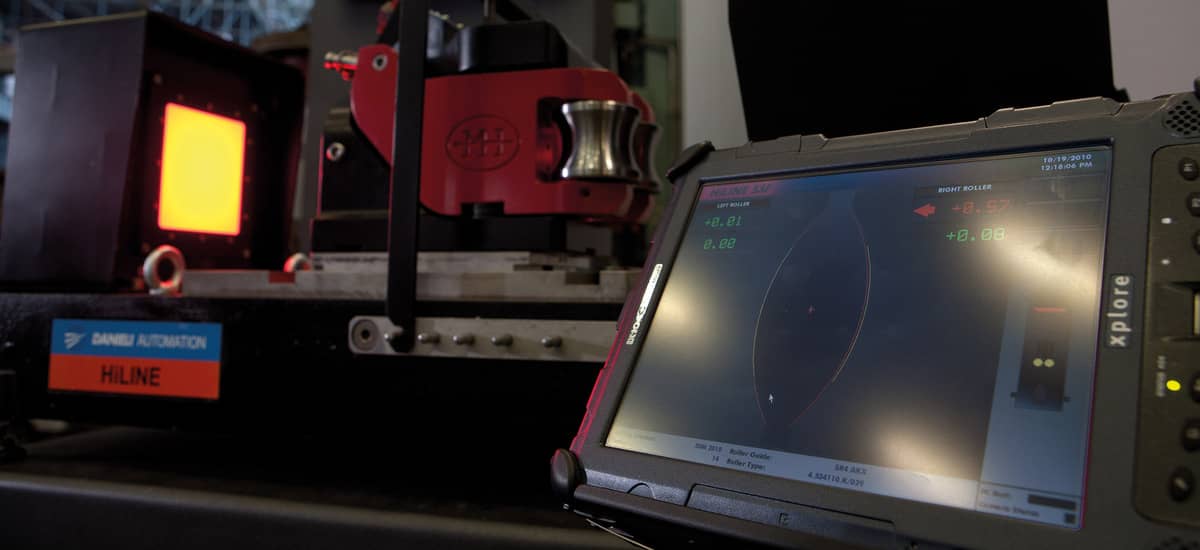

HiLINE IFB

Roller guide calibration and alignment system

HiLINE IFB is a calibration system designed to aid the operator during set-up of the roller guide in a workshop, and the alignment of the roller guide mounting bases in fast finishing blocks.

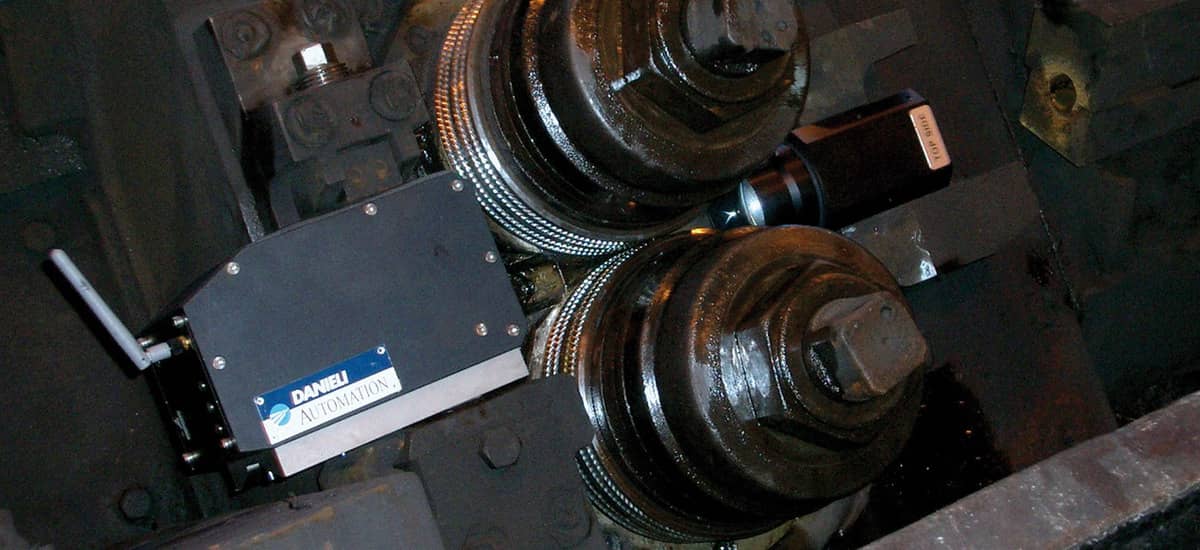

HiLINE system is based on the image acquisition of the shadow produced by the pass rings and guide rollers when these intercept the band of light diffused by the light source. Starting from this image, the processing system (Tablet PC) reconstructs the pass shape and compares it with the design drawing retrieved from the device database. Operator is provided with the necessary information to make any correction to the position of the rollers of the guide or the finishing pass mounting base. HiLINE user will be able to modify the embedded database in order to keep the system updated with the last modifications performed in mill production (e.g. roller guides, ring profiles, gap changes). Solid portable camera and tablet terminal permit to work in difficult conditions or hostile environments. Fully computer assisted step-by-step procedures guide the user to align and set the correct roller guide positions. The operator interface is user-friendly and easy to navigate, thanks to clear graphical and visual indication of shape and dimensions of the actual and target roll-groove, achieving the operator an easy and correct setup.

- Numerical indication of the main dimensions of the roll-groove for 2 or 4 rolls roller-guide

- Numerical indication of entry guide mounting base and roll-groove misalignment

- Numerical indication of the main dimensions of the roll-groove on the fast finishing block

- High measurement accuracy

- Wireless modules aid the operator during set-up of the fast finishing block

- Reduced wear in roll and bearings

- Faster rolling mill adjustment

- Accurate operator-independent alignment of the rolling equipment

- Less skilled personnel can be used for mill operation

- Improved control over product

- Improved quality

- Significant reduction of production downtime

- Quality control reporting capabilities

- Low operating and maintenance costs