LONG PRODUCTS

Extrusion presses for steel and titanium

60/118

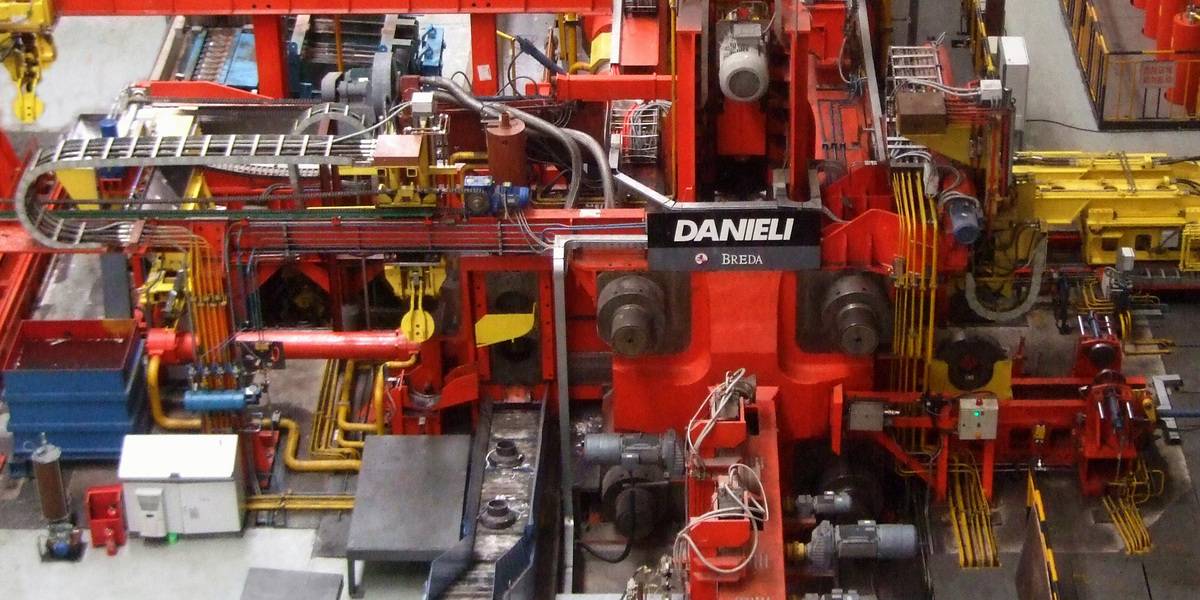

Danieli Breda also designs extrusion plants for seamless stainless steel tubes and profiles. Where extruded products are required for special applications such as the transportation of corrosive media and high temperatures (mostly for the chemical and the petrochemical industry), nuclear power and thermal power plants.

Danieli Breda extrusion presses are designed with the following principles in mind:

- Maximum rigidity: the press frame is designed to minimize die deformation

- Vertical inner hole expanding press

- Horizontal extrusion press, with lubricated glass billets

- Container cleaning and lubricating arm

- Internal piercer

- Water or oil hydraulic drive

- Reduced idle time between extrusion cycles to increase productivity

- Closed-loop feedback control of all movements over the entire stroke to guarantee extremely accurate positioning in all working conditions

- Full management in automatic mode

- Accurate, stable container and stem alignment in all working conditions

- Perfectly-balanced container sealing against the die through the combined action of four hydraulic cylinders

- Forged parts eliminate or minimize metal fatigue, even after many years of service

- Redundancy of all important safety systems

- Energy control system to reduce and optimize oil flow and energy consumption.