CROSS PRODUCTS

Dan-Wheels

DAN-Wheels manufacturing process: from material selection to quality assembly

DAN-wheels are the crane wheels engineered and produced by Danieli to meet the highest standards of quality and durability, making them a preferred choice for various industrial applications.

At Danieli, we've taken our commitment to quality manufacturing to the next level with the establishment of a specialized center of excellence within Danieli Thailand's plant.

This dedicated shop is focused on crafting long-lasting wheels to meet the most demanding industrial needs. Our manufacturing process adheres to the Danieli standard, ensuring top-notch quality. Additionally, we are flexible and ready to accommodate customer-specific requests and specifications, fitting your requirements to our proven manufacturing process.

Main features

- Dedicated engineering and In-house manufacturing

- Designed for Danieli Cranes, Cranes supplied by others and transfer cars

- Possible customizations according to specific needs

- Guaranteed short lead time thanks to complete in-house process

- Possibility to supply both complete wheel group or body wheels only

- Endurance and Quality: step-by-step quality control to assure best quality to final product

Production process

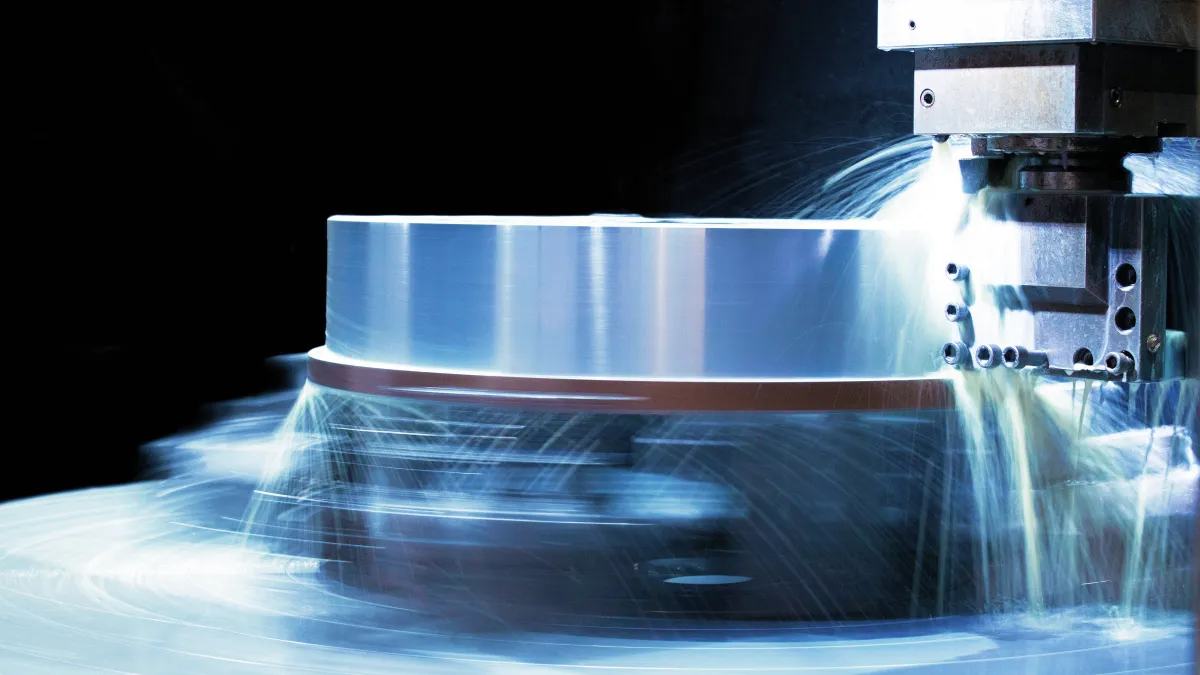

The first step is to acquire high-quality raw materials. In this case, the materials are sourced from the ABS plant in Italy, which is part of the Danieli Group. These materials form the foundation for the subsequent manufacturing process. Once the raw materials are obtained, the forged round bars are carefully cut to the required dimensions. Precision cutting ensures uniformity and consistency in the components. Before further processing, the inner holes and wheel profiles are pre-machined. This step involves shaping and preparing the components for subsequent treatments. Heat treatment is crucial for enhancing material properties. Induction hardening increases surface hardness, while stress relieving minimizes internal stresses. Both processes contribute to the durability and performance of the final product. After heat treatment, the components undergo final machining. This step involves precision shaping, drilling, and finishing to achieve the desired specifications.

Finally, the components are assembled into the finished product. Rigorous quality control ensures that each unit meets the required standards before it leaves the production line.