IRONMAKING AND STEELMAKING

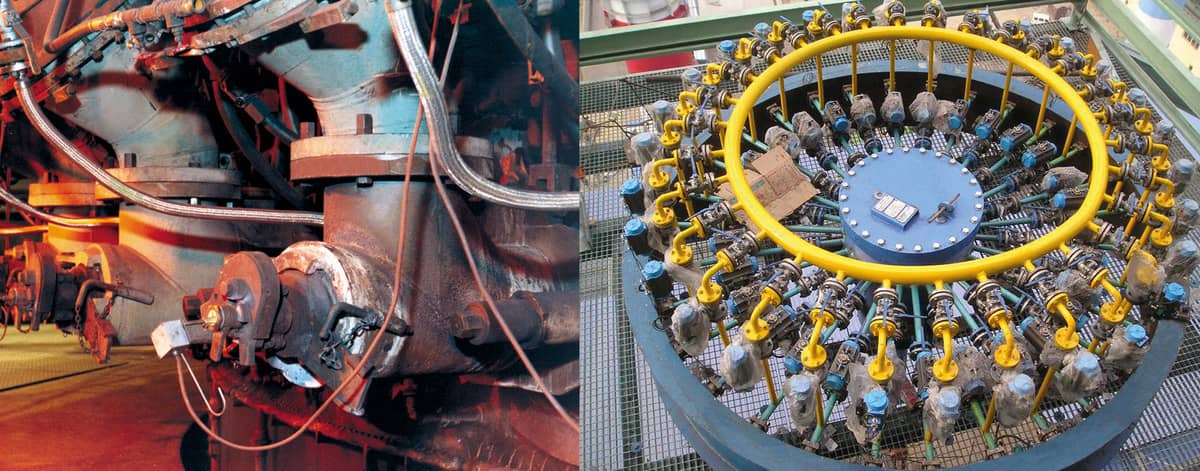

Pulverized Coal Injection

Pulverized Coal Injection is the key to optimizing the blast furnace process for high productivity as well as hot metal cost. The Danieli Corus PCI technology offers the highest proven, sustained injection rates in the industry.

Pulverized coal injection is an essential instrument for modern blast furnace ironmaking. The benefits of reducing coke consumption and increasing production are recognized by the industry. The Danieli Corus system is based on straight-forward physical principles to achieve equal coal to-gas ratios in front of the individual tuyeres.

Regardless of whether the injection system is based on dense or dilute phase, the choice for which is entirely up to the steel producer, the system is based on equal pressure drop over the injection lines from distributor to tuyeres. The simplicity of this system leads to very low maintenance costs and excellent availability of greater than 99%. This is achieved in part due to the absence of moving or modulating parts in contact with coal, which can be very abrasive. Recent improvements to the coal storage and feeding system and the distributor have further stabilized the system’s feed rates, which in turn has further stabilized the system’s injection rates.

- Highest sustained injection rates over 200 kg/thm, reducing the consumption of metallurgical coke to as low as 300 kg/thm.

- Record-breaking blast furnace productivity, up to 4 thm/m³wv.d.

- Highest availability and minimized maintenance requirement.