Low-carbon BF ironmaking: coke-oven gas injection

Danieli Corus coke-oven gas injection to reduce carbon emissions, enhance efficiency and reduce operating costs.

The use of Coke-Oven Gas (COG) to produce electricity from the captive power plant or for various heating purposes within the integrated steel plant is a possible, but not optimal, use of coke-oven gas from a CO2 emission-reduction perspective. Coke-oven gas injection in the blast burnace is a Danieli Corus innovative solution with unique characteristics that reduce the carbon footprint while lowering operating costs.

The injection of hydrogen-rich coke-oven gas into the blast furnace reduces the carbon rate and CO2 emissions, as coke or coal will be partially replaced by the hydrogen in coke-oven gas.

You can do so by followingand dragging the slider to the right

Carbon footprint can be lowered by injecting COG up to 50 kg/tHM (higher rates are possible if more coke-oven gas is available), and operating costs can be reduced by decreasing coke consumption by 30 kg/tHM.

Furthermore, coke-oven gas injection is easy to be implemented in existing plants, with minimal modification and relatively low CapEx investments.

Danieli Corus offers industry-leading expertise to seamlessly integrate coke-oven gas injection technology, to achieve sustainable goals while maintaining productivity and profitability, consisting of:

› Blast-furnace operation assessment.

› Coke-oven gas quality and quantity analysis.

› Optimal coke-oven gas-injection evaluation to achieve

significant reduction in CO2 emissions and coke consumption.

› Performance evaluation of the new coke-oven gas-injection system.

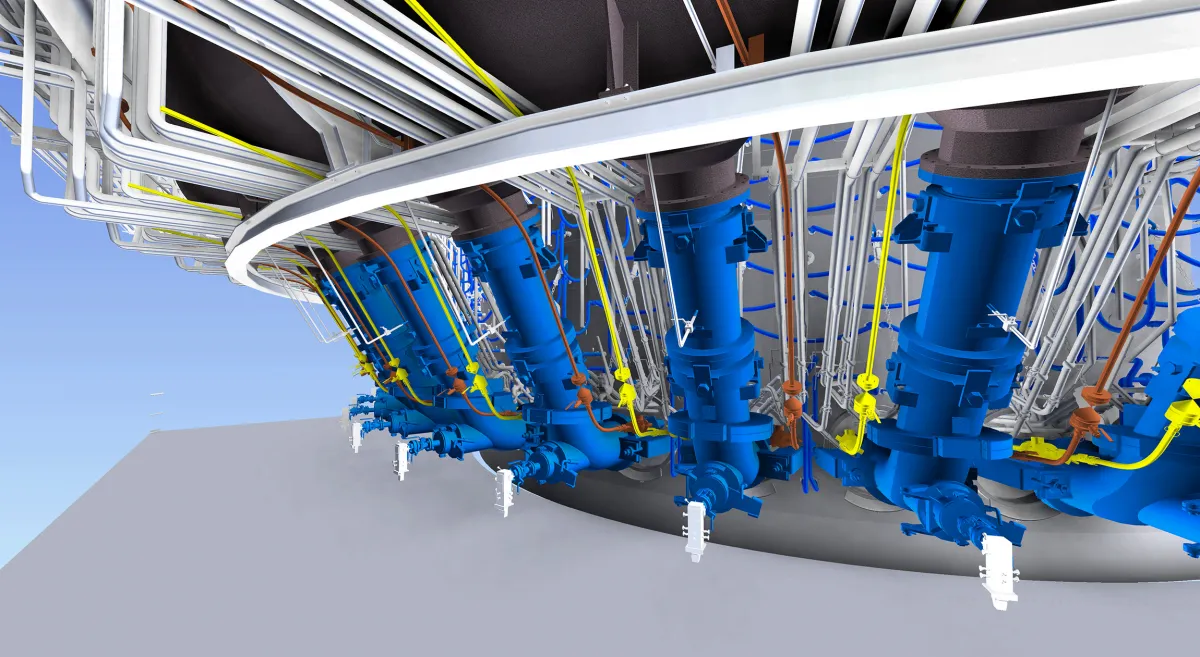

› 3D analysis of the new integration of coke-oven gas-injection system

within the existing facilities.

› Complete engineering and supply of coke-oven gas compression and injection system.

› Operational assistance during commissioning and operation.

› Comprehensive training focused on coke-oven gas-injection rate maximization.

Coke-oven gas injection

up to

50 kg/tHM

and more

-30 kg/tHM

Coke consumption

for lower OpEx