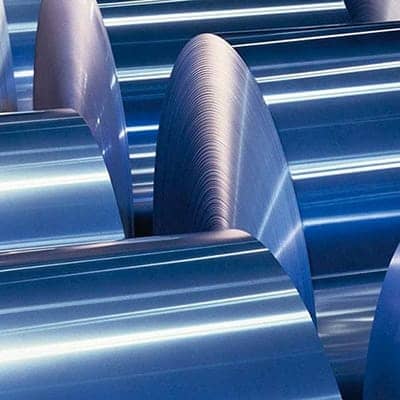

Processes and Technologies

Work culture

and passion for metals

Danieli has matured, maintained, and promoted its positive attitude to work and passion for steelmaking. These are attributes that cannot be bought or learned; they have been bred into the company’s character from the beginning, and have emerged as our most valuable, intangible asset.